Industrial automation has a lot of advantages. Automated systems can decrease energy consumption and increase efficiency, improve production output, and lower the number of mistakes that might occur on a line. But industrial automation is also quite versatile. It’s not limited to a single function.

In fact, industrial automation is so versatile, that it sometimes finds its way out of factories and plants and is put to work in an entirely different application. Who would have thought that custom cars could benefit from industrial automation?

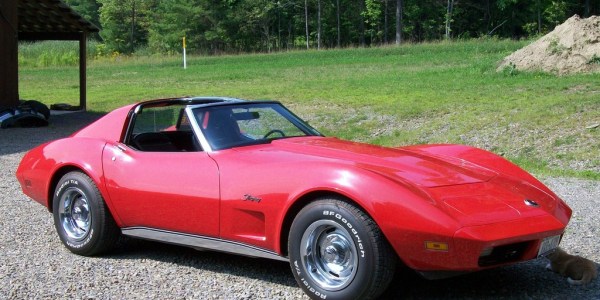

If you’re not familiar with custom cars, they can be quite surprising. Sure, they might just take an old Stingray, lather it with a beautifully unique color, add a little chrome, and call it custom, but that’s just the beginning. Custom car builders are taking advantage of the versatility that industrial automation brings to the table.

A majority of custom show cars are going to be relatively old, or at least old enough to predate on-board computers and electrical everything. So, custom car guys are taking it upon themselves to give these old cars all electrical everything, and make you forget that an era without power windows ever existed. They’re finding that industrial automation is the best, and easiest, way to hook up the electronics in these old cars.

Let’s say that you want to hook up a 1974 Stingray with electric start up, shut down, a water pump, thermo fans, and you want to control the raising and lowering of the trunk and hood, all via remote control. Well, needless to say, a car made in 1974 did not come with this feature. A custom car builder will have to set up the electronics, which could take nearly 20 separate toggle switches to perform all of those functions.

Or, instead of using 20 toggles, that custom car guy could use industrial automation controls. That’s a testament to the versatility and value of automation controls!