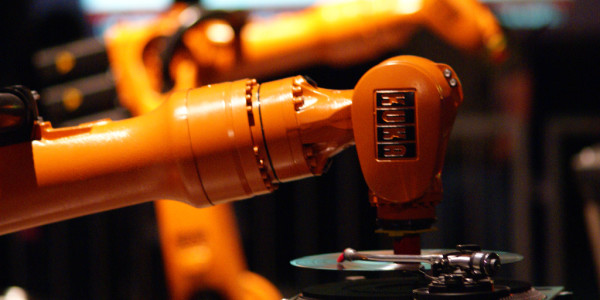

Manufacturing would not be where it is today without industrial robots. Automation has made some truly incredible things possible in terms of speed, productivity, efficiency, and consistency. As amazing as industrial robots have become over the past few decades, they are only continuing to improve. But they’re not just getting better. Industrial robots are changing.

The manufacturing industry is gearing up for Industry 4.0. This next chapter in the history of industry is focused on gathering, processing, and applying information. The industrial robots that we’ve grown accustomed to – those big, dangerous robots with swinging arms that plug away all day doing the same repetitive tasks – are not going to be able to satisfy all of the changing needs of manufacturing.

Collaborative robots are being brought into factories to address these new needs, and are redefining what we know industrial robots to be.

Price has been one of the biggest issues with industrial robots. Typically, industrial robots are too expensive for smaller manufacturers to bring them into plants. This is changing with collaborative robots. While by no means cheap, collaborative robots are certainly more affordable than traditional industrial robots, and affordable enough to be a viable option for small manufacturers.

These new robots are also more versatile than traditional industrial robots. Collaborative robots are better able to adapt to different environments and can perform multiple tasks without expensive reprogramming.

They’re also much more intuitive and user-friendly than old-school industrial robots. They use vision software and sensors to learn new tasks, rather than relying on complicated codes.

Unlike industrial robots, collaborative robots are safe. In fact, they are designed to be used alongside human workers to optimize their work. This is a big difference from industrial robots that require barriers or safety cages.

Collaborative robots won’t replace the need for industrial machinery, however. Your motion control system will still be a vital part of your manufacturing process. If it’s an Indramat system, we can help make sure that it’s running smoothly.

image by Vincente Diamante