People and machines learn to do things in very different ways. Humans learn new skills through research, or taking lessons, and practicing until they’re good at it. Robots, computers, and machines don’t need practice, however. Robots immediately master a task once programmed to do so. While you may secretly wish you could program yourself to master ballroom dancing or a foreign language with the push of a button, programmed learning does have its drawbacks. If something varies even slightly from what a machine is programmed to know, the machine won’t know it. A robot programmed to fold shirts that are perfectly flat won’t be able to fold a shirt that’s in a wrinkled heap. That robot might not even recognize the shirt as a shirt at all. Machine learning could be the solution to this problem, which could benefit manufacturing.

What exactly is machine learning?

Machine learning is type of artificial intelligence that allows machines to adapt, change, learn, and make decisions and predictions without explicit programming. Machine learning, in a sense, allows machines to teach themselves with data through experience. This happens through the use of systems and algorithms. Machine learning looks for patterns, and tries to make sense of data.

While this is still different from how humans learn, machine learning would allow for more flexibility and adaptability from robots and machines. Transportation, medicine, and manufacturing are just a few of the areas that will benefit from machine learning.

How can machine learning help manufacturing?

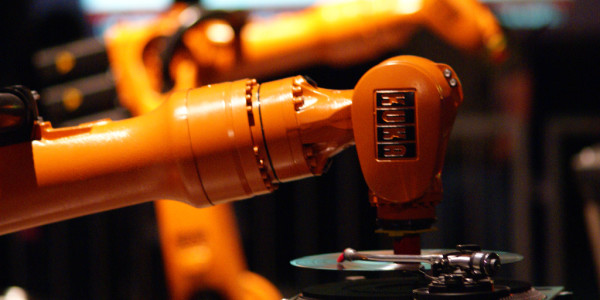

The next industrial revolution – Industry 4.0 – is well underway. Machine learning is a prime example of IIoT at work. The information has always been there, but it hasn’t been used as efficiently as it should be used. Automating the collection of data and implementing the learned information will greatly benefit manufacturing. Machine learning lends itself to increased production, reduced material waste, more informed decision making, real time adaptability, improved efficiency, and increased accuracy.

Are you ready for Industry 4.0? Contact us today for any of your Indramat service needs!