What did vibrations ever do for anybody? Earthquakes are vibrations that rattle buildings to the ground and cause bridges to topple over. Vibrations cause massive tsunamis that destroy entire cities with a quivering wall of water. Vibrations can ruin a perfectly good game of Jenga. Wouldn’t it be great if there were some way to just cancel vibrations? Well, we’re in luck.

To be fair, not all vibrations are bad. You couldn’t listen to your favorite song without vibrations, but when it comes to packaging, vibrations are the last thing that you want.

There are plenty of perks that come with packaging robots. They don’t call in sick to work, they don’t need to take breaks, and they can work much faster than a human worker. However, that last benefit seems to be a little limited.

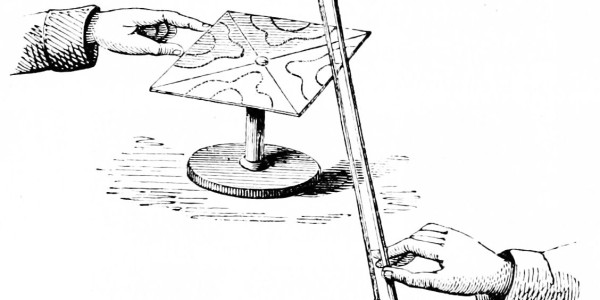

When you increase the speed of a packaging robot, you also increase the amount of vibration that is produced. The more vibration there is, the harder it is for the robot to accurately and effectively package products. So, while a packaging robot can work faster than a human, vibrations prevent it from working as fast as it possibly can.

It’s nearly impossible to get a packaging robot moving at a fast pace without creating vibrations on the end effector. Bosch Rexroth’s anti-vibration technology is the solution to that problem. Dampening vibrations can reduce part damage, prevent tool wear, decrease cycle time, and improve precision. Machines that were equipped with this anti-vibration technology saw an increase in throughput by 33%, going from 30 parts per minute to 40 parts per minute.

There are basically two different ways to not have vibrations. You can either prevent it, or you can dampen it. Right now the only way to prevent vibrations from occurring is to decrease the speed of the machinery. If you want to have your packaging machines running faster, you have to cancel the vibrations that occur. Right now this is the only technology on the market that can cancel vibrations at the drive level.